Heated or unheated pressure compensation valves for more safety - also in the EX sector.

Features and benefits

- Reliable pressure compensation

- Reliable up to - 30°C

- Heated or nonheated

- Can be mounted on either wall or ceiling

- EX-version also available

- Made in Germany

- VDE-approved

Do you have any questions or like to place an order?

General questions

07135/98 98 0 or office@hemstedt.de

Question about our products

inquiries@hemstedt.de

Orders

orders@hemstedt.de

Pressure change in deep freeze chambers

The periodic defrosting of air coolers, as well as the transport of goods with higher temperature into deep freeze chambers, leads to substantial pressure changes. Those can be especially dangerous for the structure, including the entrance areas, if the cooler in an air-sealed deep freeze chamber was covered in rime and has to be heated accordingly for proper defrosting. During the defrosting process, water vapor forms, which increases air pressure in the deep freeze chamber. Under normal circumstances, pressure has compensated by the time the cooling unit is restarted.

After the restart of the cooling unit, when air temperatures are lowering, some of the water vapor that has formed will condense, creating negative pressure. For the limitation of the negative pressure in the entrance area, air must be able to flow into the deep freeze chamber. This is achieved with a pressure compensation valve.

500Pa of pressure fluctuations have been measured in deep freeze chambers without pressure compensation valves. Normally - with the right pressure compensation valves - the force caused by the pressure has to be restricted to ca. 120Pa, so it doesn't exceed the weight force of the ceiling. Accordingly, occurring negative pressure exceeding the permitted ceiling load has to be compensated through the pressure compensation valves.

Measures to minimize pressure fluctuations in deep freeze chambers

• Limitation of the occurring pressure, both positive and negative, through appropriately chosen pressure compensation valves (for example, Hemstedt Article-No. 11100, 11830 and 11500) with in-built antifreeze heating protection, normally to 100 Pa. Higher values for the differential pressure may only be chosen in case of high load-bearing capacity of the structure, though that makes opening doors difficult in case of negative pressure and can force them open in case of positive pressure.

• Turning on cooling unit and fan with a delay. Through pre-cooling the evaporator - before restarting the fan after defrosting - residual humidity or warmth is kept away from the air inside the deep freeze chamber.

• Frequent defrosting of the air coolers with minimal heat supply so the temperature fluctuations that cause pressure changes to a minimum.

Mounting position of pressure compensation valves

The pressure compensation valves are best placed next to doors or other access possibilities, about halfway up the wall. With newer pressure compensation valves that already open at low differential pressure, (for example Hemstedt item no. 11100, 11830 and 11500) no problems with opening or closing the doors are to be expected.

FAQs Pressure Compensation Valves

Discover today how our emergency alarm devices can make your freezer room safer and more efficient. We answer your questions around the clock in our new FAQ section! Our FAQs offer quick and convenient ways to answer questions about functionality, technology and utilisation. The FAQ compendium is continuously updated to provide you with the latest information. With Hemstedt, you not only have innovative technology at your disposal, but also a service focussed on your needs. Discover our wide range of products and experience quality and service at the highest level!

Hemstedt - always one step ahead in cold store technology.

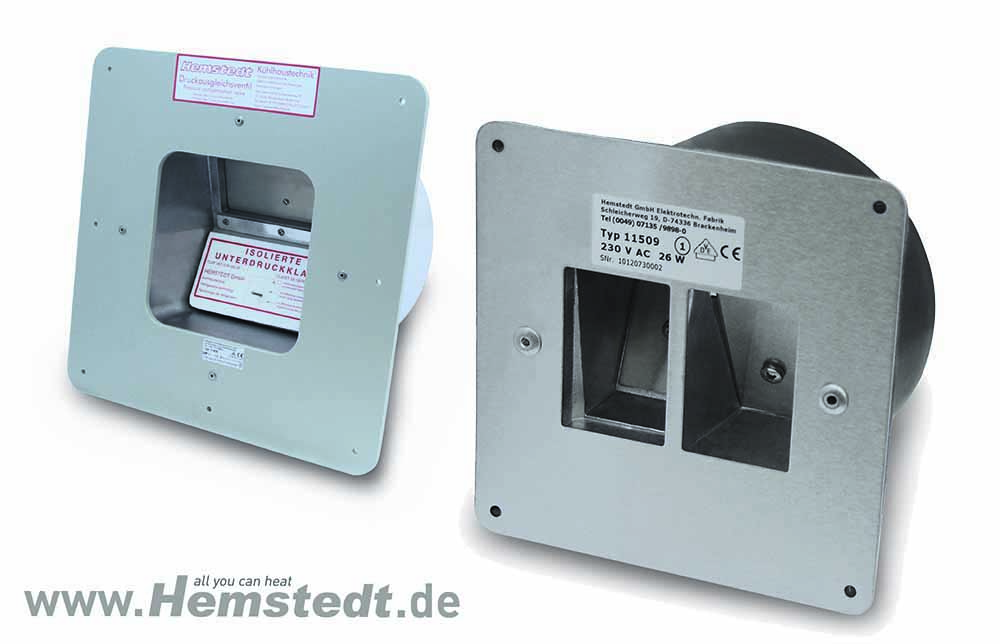

Technical Data HEM-DAV I PRESSURE COMPENSATION VALVES Item no. 11106, 11109, 11289

| System of protection | IP 65 |

| Safety class | II |

| Silicone connecting cable | 2 x 0.75 mm² |

| Mains voltage | 230 V |

| Output | 16 Watt |

| Temperature controller | max. 80 °C |

| Diameter | 90.0 mm |

| Installation depth | 76.6 mm |

| Air grille square | 111 mm |

Technical Data HEM-DAV II PRESSURE COMPENSATION VALVE Item no. 11506, 11509, 11526

| System of protection | IP 65 |

| Safety class | II |

| Silicone connecting cable | 2 x 0.75 mm² |

| Mains voltage | 230 V |

| Output | 26 Watt |

| Temperature controller | max. 80 °C |

| Diameter | 160.0 mm |

| Installation depth | 76.6 mm |

| Air grille square | 140 mm |

| Different wall thicknesses | Compensation with extension tube |

Technical Data HEM-DAV II PRESSURE COMPENSATION VALVE for ceiling installation item no. 11516, 11519, 11528

| System of protection | IP 65 |

| Safety class | II |

| Silicone connecting cable | 2 x 0.75 mm² |

| Mains voltage | 230 V |

| Output | 26 Watt |

| Temperature controller | max. 80 °C |

| Borehole diameter | 120.0 mm |

| Installation depth | 76.6 mm |

| Air grille square | 140 mm |

| Different wall thicknesses | Compensation with extension tube |

Technical Data HEM-DAV III PRESSURE COMPENSATION VALVE Item no. 11830, 11834

| System of protection | IP 65 |

| Safety class | II |

| Silicone connecting cable | 2 x 0.75 mm² |

| Mains voltage | 230 V |

| Heating connection cable | Silicone insulated (color: white) |

| Alarm thermostat connection cable | Silicone insulated (color: red-brown) |

| Output | 115 Watt |

| Temperature controller | max. 80 °C +/-5 K |

| Alarm thermostat | 5°C EIN/15°C +/-3 K |

| Bore diameter | 315.0 mm |

| Installation depth | 170.0 mm |

| Dimensions cover plates | 400.0 mm |

| Different wall thicknesses | Compensation with extension tube |